Learn how Tiffany & Co. employed the metalworking technique of champlevé enameling with illustrative artworks and process demonstrations.

Tiffany & Co. (American, 1837–present). Teapot, ca. 1887. Silver, silver-gilt, enamel and ivory, 4 3/4 x 10 7/8 x 5 1/8 in. (12.1 x 27.6 x 13.2 cm). The Metropolitan Museum of Art, New York, Gift of a Friend of the Museum, 1897 (97.1.1)

Enameling describes the technique of using heat to fuse frit, powdered glass, to the surface of a metal object. In champlevé enameling, a recess is etched, cast, or carved into the body of the metal substrate to be filled with frit.

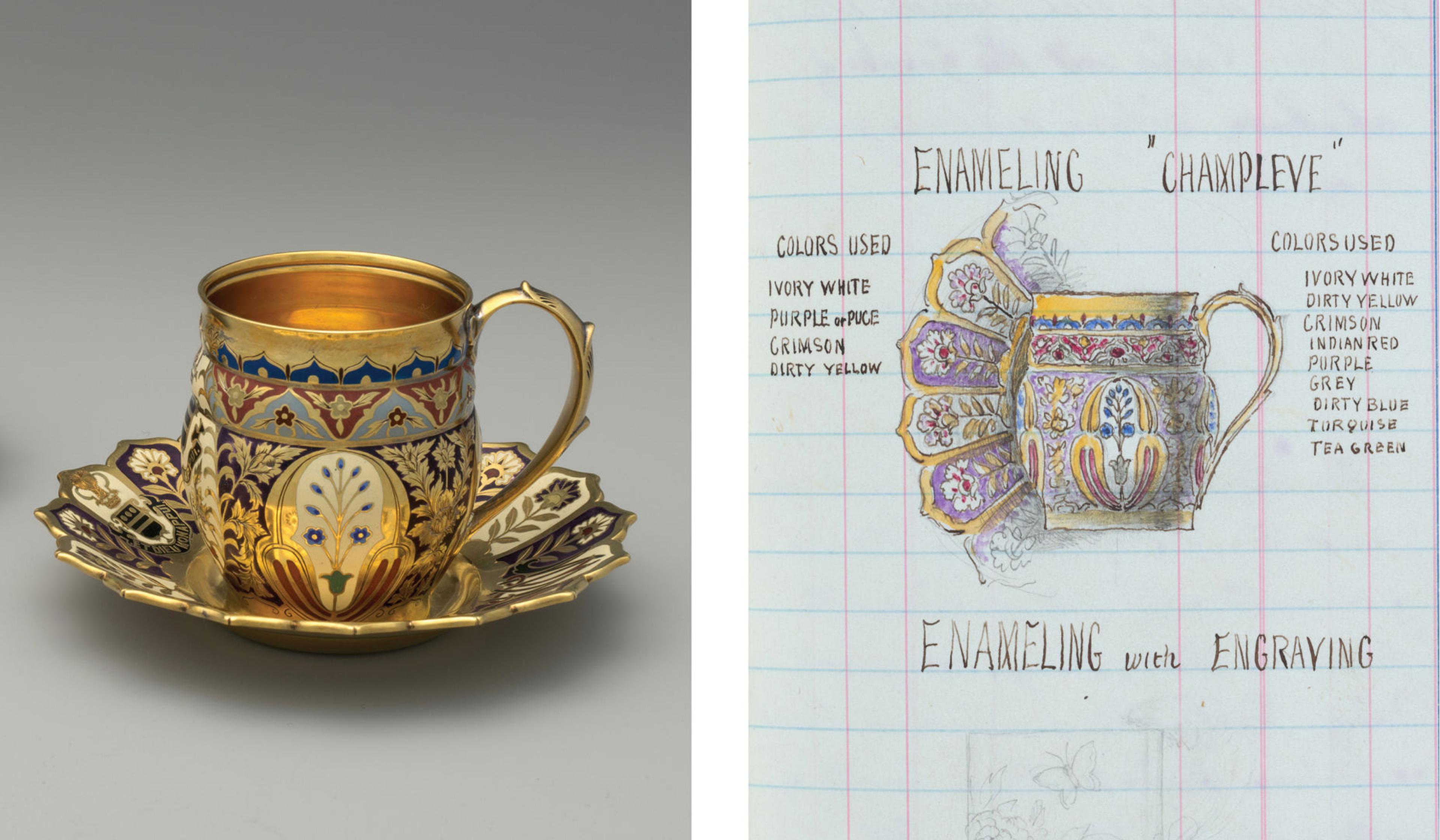

Enameling is one of the oldest decorative techniques seen across cultures, and it was embraced by designers in the nineteenth century. Edward C. Moore, chief silver designer at Tiffany & Co., was extremely innovative with his work in enamel and even pioneered a technique to create matte finishes. One example of his use of champlevé are the demi-tasse cups from the 1,250-piece Mackay Service, made in 1878.

Left: Tiffany & Co. (American, 1837–present). Two cups and saucers from the Mackay Service (detail), 1878. Silver, silver-gilt and enamel, 2 1/2 x 2 x 2 3/4 in. (5.7 x 5.1 x 7 cm). The Metropolitan Museum of Art, New York, Purchase, Cranshaw Corporation Gift, 2017 (2017.196.1-.4) Right: “Enameling ‘Champleve,’” depicting Mackay Service cup and saucer. Tiffany & Co., Technical Manual, p. 315 (detail). Gorham Company Archive, John Hay Library, Brown University, Providence, Rhode Island

To prepare a metal surface to be enameled, it must be cleaned to remove any fingerprints or grime. In champlevé, a recess for the frit needs to be created in the object. This can be done mechanically (by removing metal from the surface with tools), by acid etching, or via electrolytic etching. The letter M has been electrolytically etched into the surface of the piece of copper below.

The enamel frit is prepared first by washing. Washing is the term used for removing the finest grains of powdered glass. These can interfere with the clarity of the final color of the enamel. The frit is poured into a mortar with some distilled water. The powder is gently ground with a pestle and swirled, allowing the heavier grains to settle to the bottom. The water at the top of the mortar is poured out, removing the fine grains along with it. This process is repeated several times.

After washing, drops of methyl cellulose are added to the wet frit to act as a binder. The wet mixture is packed into the recess using a spatula, pick, or brush. Once the recess is full, the object is placed in a kiln and fired.

After a few minutes in the kiln the enameled object is removed and allowed to cool. In the kiln, the wet-packed frit will have become vitreous enamel. Excess enamel on the surface is reduced by stoning, the process of evening out or removing enamel from a surface with an abrasive alundum stone.

Once all the excess enamel is gone, the slurry from the polishing process is rinsed off, and the newly enameled object is wiped dry.

See the final enameling and illustrative cups and saucers from The Met collection:

Watch a video of the entire enameling process below, including an introduction to the preceding step of electrolytic etching: