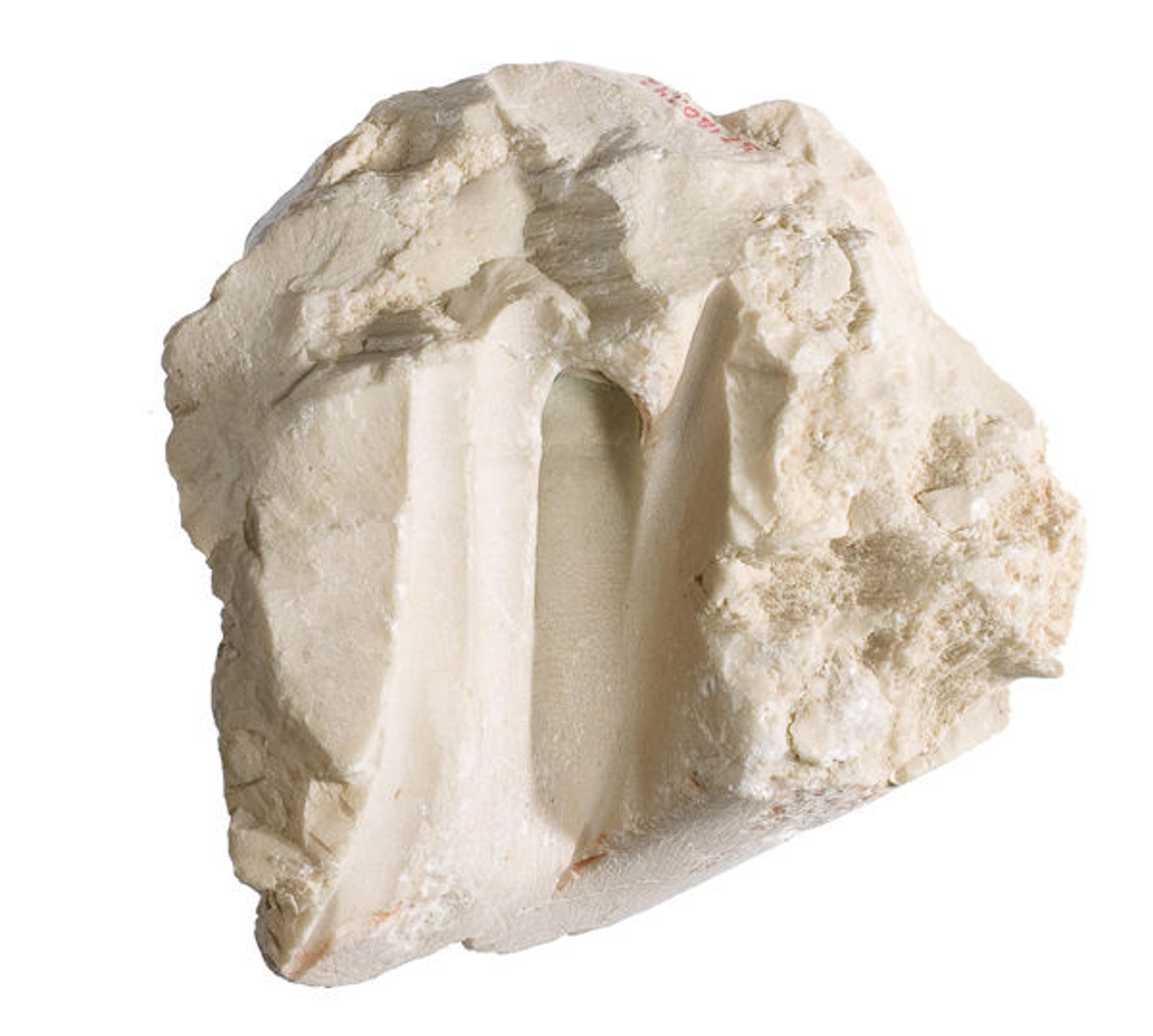

Fig. 1. Fragment with working traces, ca. 1353–1336 B.C. Egyptian, New Kingdom, Amarna Period, Dynasty 18. Indurated limestone; H. 8 x W. 7 x D. 6.3 cm. The Metropolitan Museum of Art, New York, Harris Brisbane Dick Fund, 1957 (57.180.142)

Archaeological objects and works of art in museum collections are not only treasured for their aesthetic qualities, but are also repositories of invaluable information, often concealed at a first sight, about the civilizations that created them. Among the many beautiful pieces in the collection of the Met's Department of Egyptian Art, it is interesting to note one modest stone fragment (fig.1), the scientific investigation of which has provided a clue that could solve a long-time debate among Egyptologists and historians of technologies: the use of high-performance abrasives.

Ancient Egyptian craftsmen were exceptionally skilled and prolific in extracting and shaping a wide variety of stones (fig. 2). For millennia, soft and hard stones were quarried, cut, drilled, carved, and polished using a variety of tools and techniques, and it is generally agreed that abrasives played a significant role. Both saws and core drills used particulate abrasives, and the finishing of sculptures and architectural elements was likely carried out with a combination of rubbing stones and abrasive slurries.[1]

Fig. 2. Fragment of right eye and brow from head of king or queen, ca. 1353–1336 B.C. Egyptian, New Kingdom, Amarna Period, Dynasty 18. Indurated limestone; H. 9.1 x D. 7.5 cm. The Metropolitan Museum of Art, New York, Purchase, Fletcher Fund and The Guide Foundation Inc. Gift, 1966 (66.99.107)

The composition of the abrasive materials used has been extensively debated, particularly in relation to the working of hard stones.[2] Were stones such as granite, diorite, and quartzite shaped and polished using solely quartz-based abrasives, or did Egyptian craftsmen have access to harder materials? It has been demonstrated through archaeological evidence and experimental data[3] that corundum and emery—mixtures of minerals with great hardness—were employed by craftsmen in the ancient Mediterranean and Near East, but were these materials part of the Egyptian tool kit?

Although some scholars posited the use of emery abrasive powder,[4] the absence of direct evidence for the use of this material in Egypt, as well as the lack of known sources of emery in Egypt and the presence of quartz sand embedded in ancient drill holes, led others to dismiss the use of emery by Egyptian craftsmen.[5]

The small fragment of indurated limestone in question from the Met's collection was excavated from a pit outside the southern wall of the Great Temple of the Aten at Amarna in 1891–92, measuring just eight centimeters in height and seven centimeters in width. The fragment is mostly shapeless, has nearly unrecognizable carved features, and no aesthetic appeal. However, it does contain important information needed to uncover the secrets of ancient Egyptian technology—one which is almost invisible to the naked eye.

This fragment has several vestiges of what resemble drill holes, cut at slightly different angles. The main drill hole is about one centimeter wide and has a protruding stump at the bottom left by a broken drill core. Lightly consolidated material, the possible remains of an ancient abrasive powder, is deposited around the stump. To the naked eye, it consists of a fine-grained, whitish powder speckled with dark, slightly coarser grains. The whole material is stained light green (fig. 3).

Fig. 3. Close-up photograph of the protruding stump of the broken tubular drill core, surrounded and partly covered by the granular material that provided the sample for analysis.

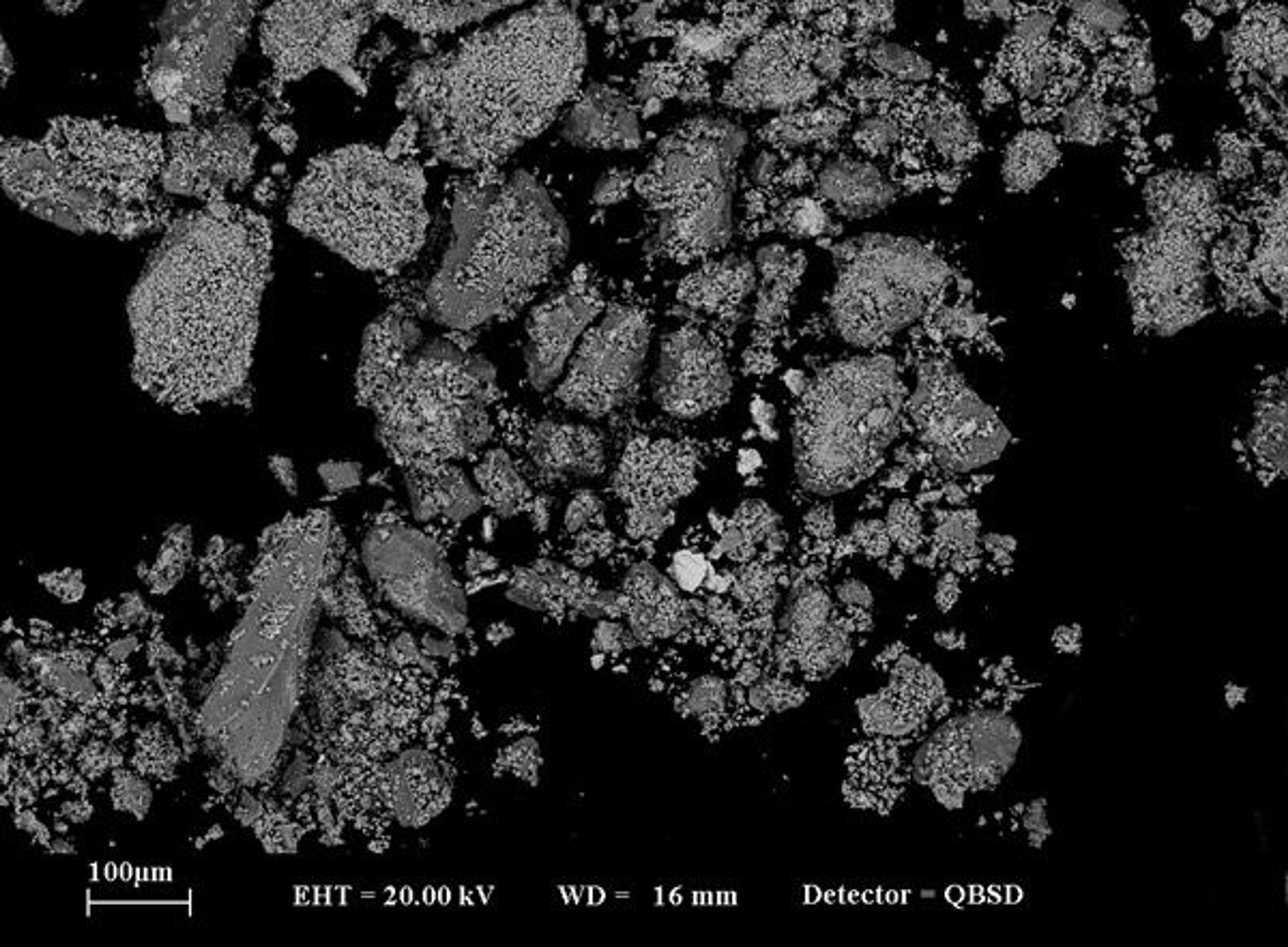

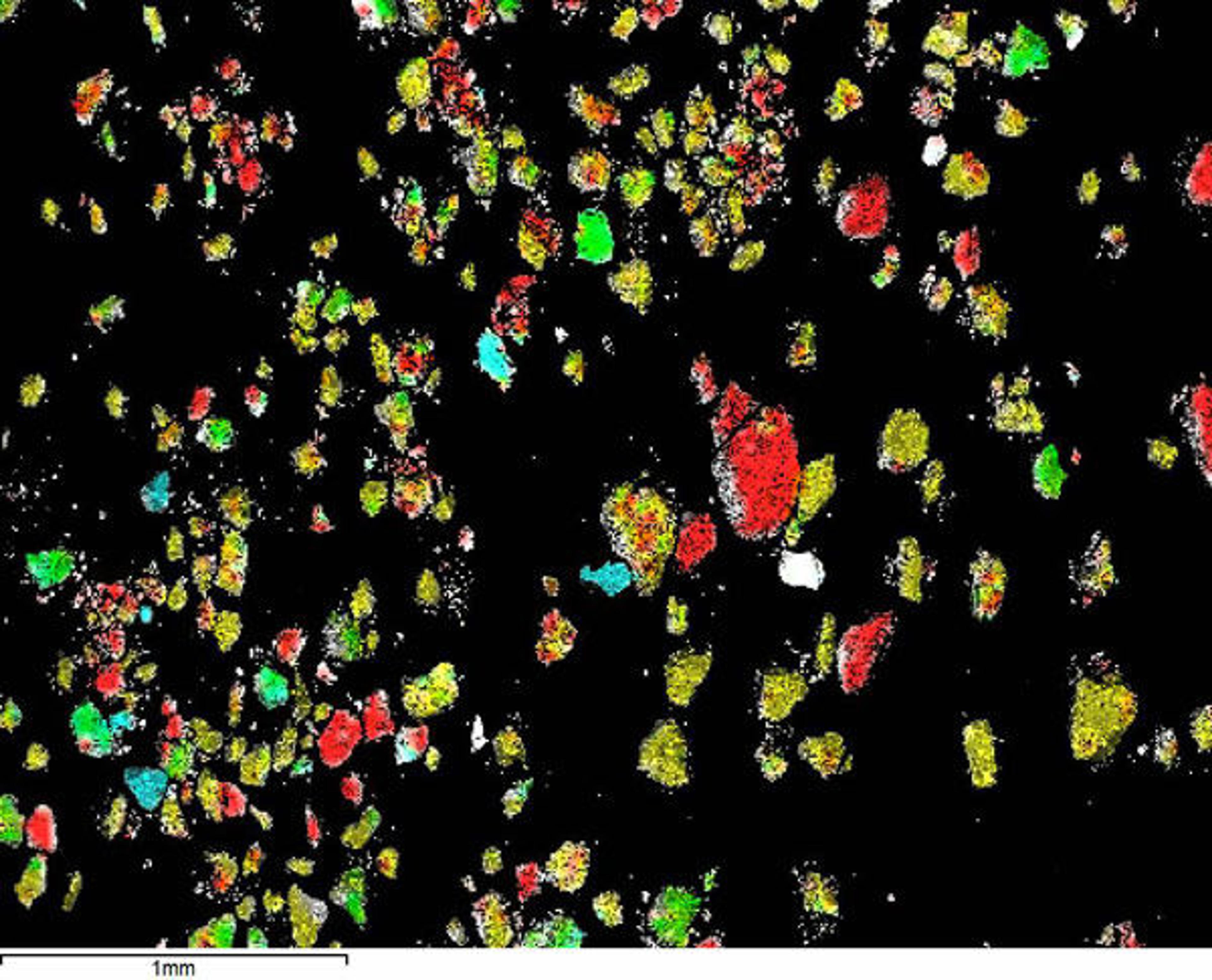

Scientific analysis, using scanning electron microscopy and energy dispersive X-ray spectroscopy (SEM-EDS), identified the material as a mixture of predominant angular grains of corundum (aluminum oxide, Al2O3) with jagged edges and a few other minerals such as quartz, rutile, feldspar, apatite, ilmenite, augite, biotite, and chromite, usually smaller in size and with high angularity (figs. 4–5). Very fine particles of calcite surround the bigger particles, which are most likely remains of the indurated limestone that had been drilled. Several particles of corroded bronze and green copper corrosion products are intimately dispersed among the above-mentioned particles, imparting the light green color.

Fig. 4. Back-scattered electron (BSE) image of the sample from the bottom of the drill hole taken at 200x. At this magnification it is possible to distinguish several angular particles 50–200 μm in size, surrounded by much finer particles <10 μm.

Fig. 5. An X-ray elemental map showing the distribution of aluminum (Al, yellow), silicon (Si, blue), and calcium (Ca, red) in the abrasive sample. The yellow particles are corundum fragments.

The presence of abundant corundum particles conveys high abrasive efficiency to this material, and strongly suggests that this mixture was deliberately used in the drilling process of the hard limestone fragment. Remains at the bottom of the drill hole thus consist of a mixture of the abrasive, the powdered limestone, and corroded fragments of the bronze drilling tool. All together, these findings suggest the use of a bronze tubular drill[6] in conjunction with a corundum-rich abrasive mixture.

Although the use of corundum would appear to be established, it is still quite difficult at this time to indicate where and how such abrasive material was obtained, although the assemblage of minerals identified can help to narrow down its plausible origin. Most of the historically exploited abrasive was in the form of emery—a complex mixture of different minerals that includes abundant corundum. The major source of abrasive in the ancient Mediterranean, located on the Greek island of Naxos, was indeed an emery deposit.[7] However, the minerals so far identified on the Amarna fragment differentiate this material from usual emery and pose some questions regarding its source, manufacture, and possible recycling history.

Among possible sources of abrasive other than emery, byproducts from the mining of gem-sized crystals could have potentially provided corundum-rich loose material with a technical and economic value of its own.[8] In Egypt, the only known corundum deposit of this type is located in the southern part of the Eastern Desert, at Hafafit.[9]

This scientific investigation continues. In order to verify the consistency of these first findings, new samples from other worked objects will need to be found and analyzed. Additionally, samples from corundum-bearing deposits, including both the well-known historical emery deposits and the lesser-known Egyptian source of Hafafit, should be analyzed for comparison.

The full report about this research was published in the spring issue (14) of Horizon, the Amarna Project and Amarna Trust newsletter.

Notes

1. A. Lucas, Ancient Egyptian Materials and Industries, 4th ed., rev. J. R. Harris (London: Edward Arnold and Mineola, New York: Dover, 1962), 66–67.

2. Summaries of this debate can be found in Lucas, 72–4; L. Gorelick and A.J. Gwinnett, "Ancient Egyptian Stone Drilling," Expedition 25 (1983): 40–47; D. Stocks, Experiments in Egyptian Archaeology: Stoneworking Technology in Ancient Egypt (London: Routledge, 2003), 105–11.

3. W. Heimpel, L. Gorelick, and A.J. Gwinnett, "Philological and archaeological evidence for the use of emery in the Bronze Age Near East," Journal of Cuneiform Studies 40/2 (1988): 195–210; L. Gorelick and A.J. Gwinnett, "Minoan versus Mesopotamian seals: comparative methods of manufacture," Iraq 54 (1992): 57–64; L. Lazzarini, "I vasi in pietra minoici di Festòs: primi dati sulla natura e provenienza dei materiali lapidei," Atti dei convegni Lincei, I cento anni dello scavo di Festòs (Rome: Accademia Nazionale dei Lincei, 2001), 575–96.

4. W. M. F. Petrie, The Arts and Crafts of Ancient Egypt (Edinburgh and London: T.N. Foulis, 1909), 74, 79. Lucas also lists other scholars who previously proposed the use of emery, including Borchardt (1905), Hölscher (1912), Junker (1951), and Reisner (1931). B. C. Aston, J. A. Harrell, and I. Shaw, "Stone," Ancient Egyptian Materials and Technology, ed. P. T. Nicholson and I. Shaw (Cambridge: Cambridge University Press, 2000), 65 (mention, in passing, emery as an abrasive).

5. Lucas, 73–4; Stocks, 110–11.

6. This tool was likely consistent with the drills described by Lucas, 66–67, and Stocks, 112–6.

7. J. J. Urai and A. Feenstra, "Weakening associated with diaspora-corundum dehydration reaction in metabauxites: an example from Naxos (Greece)," Journal of Structural Geology 23 (2001): 941–50.

8. John Twilley, personal communication.

9. El Shazly, et al., "Mineralogical study of corundum, zincian hercynite and andalusite from pegmatites of Hafafit, Egypt," Egyptian Journal of Geology 19 (2) (1975): 153–68.

Related Links

Met Blogs: Blog posts related to the Department of Scientific Research, the Department of Objects Conservation, and the Department of Egyptian Art