A 2012–2013 pilot archaeological excavation by the École française d'Extrême-Orient (EFEO) and University of Sydney in the World Heritage Site of Angkor has discovered the location of the first historical bronze workshop in all Southeast Asia. Located next to the Royal Palace of Angkor Thom, the first identified royal workshop of Angkor and the region was of considerable importance to the political elite who commissioned its products to furnish its palaces and temples with objects, and to legitimize its rule with images of the gods.

In July 2016, the EFEO, together with several other participants, among which The Metropolitan Museum of Art, the Authority for the Protection and Management of Angkor and the Region of Siem Reap (APSARA), the Centre de recherche et de restauration des musées de France (C2RMF), the Musée national des arts asiatiques – Guimet, the Museum Conservation Institute, Smithsonian Institution, the University of Sydney, and the National Museum of Cambodia, started a new four-years research project to fully characterize this unique site.

The excavation site next to the Royal Palace of Angkor Thom (left), and examples of crucibles that are being studied at The Met (right).

Among the goals of the project is the archaeometallurgical research of this workshop that produced sacred idols, ritual paraphernalia, adornments for utilitarian objects, and temple decorations in a period comprised between the mid-eleventh and the beginning of the twelfth century. The study of this unique metal production site aims to characterize the metallurgical techniques privileged by Angkorian bronze casters to manufacture both statues and objects, and investigates the degree of coordination and influence between the Royal Palace and its attached craft specialists. In this framework, the Department of Scientific Research Department at The Met is studying crucibles, tuyères, molds, furnace walls and floors collected during the excavation. This investigation is complemented by a typological study by Khmer archaeologists.

Until now, one forge and ten furnaces have been discovered, casting copper, bronze and leaded bronze objects. The investigation of ceramic (crucibles) and non-ceramic (molds and furnace walls and floors) materials includes:

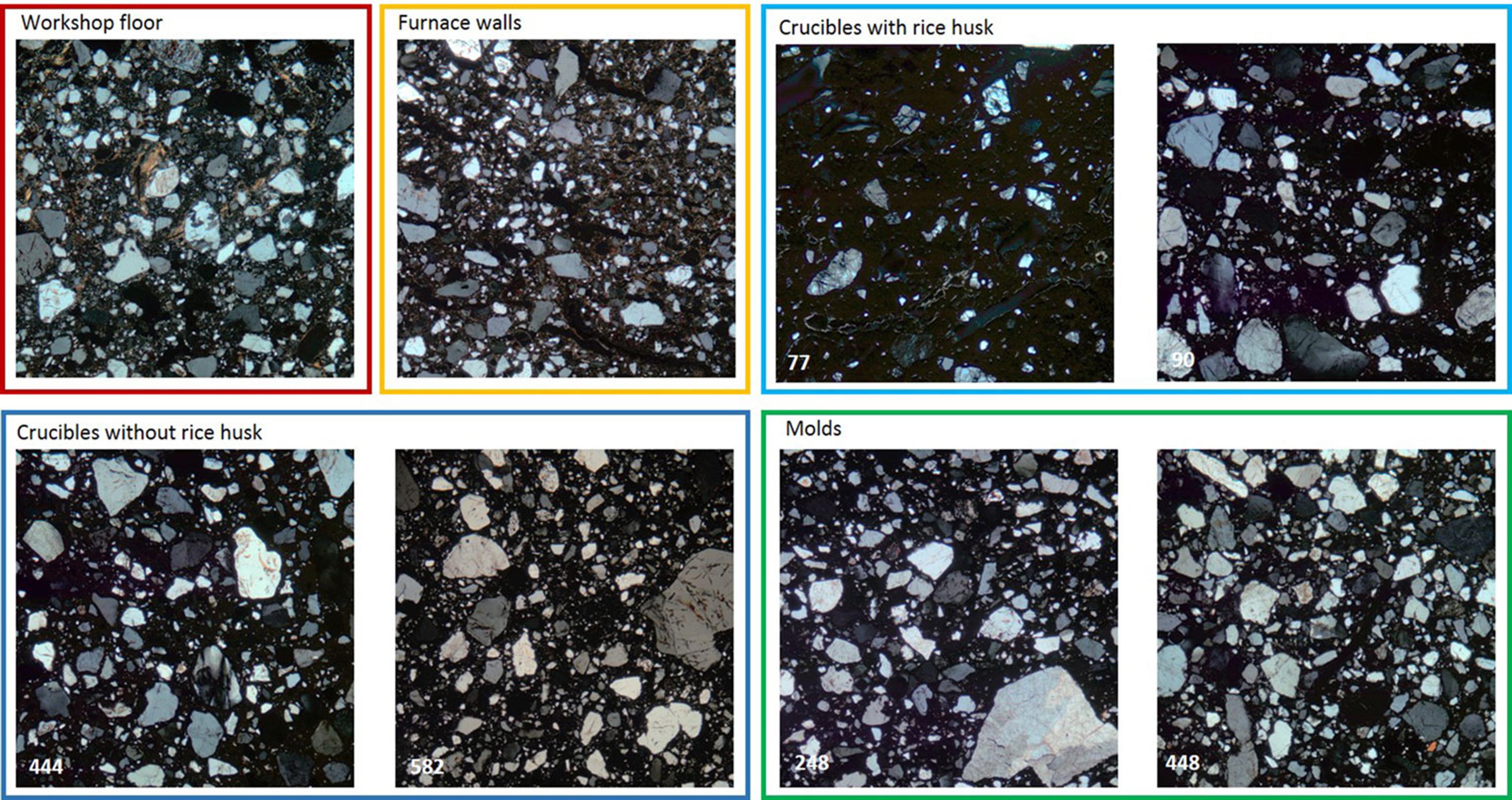

- textural and compositional analysis by petrographic microscopy;

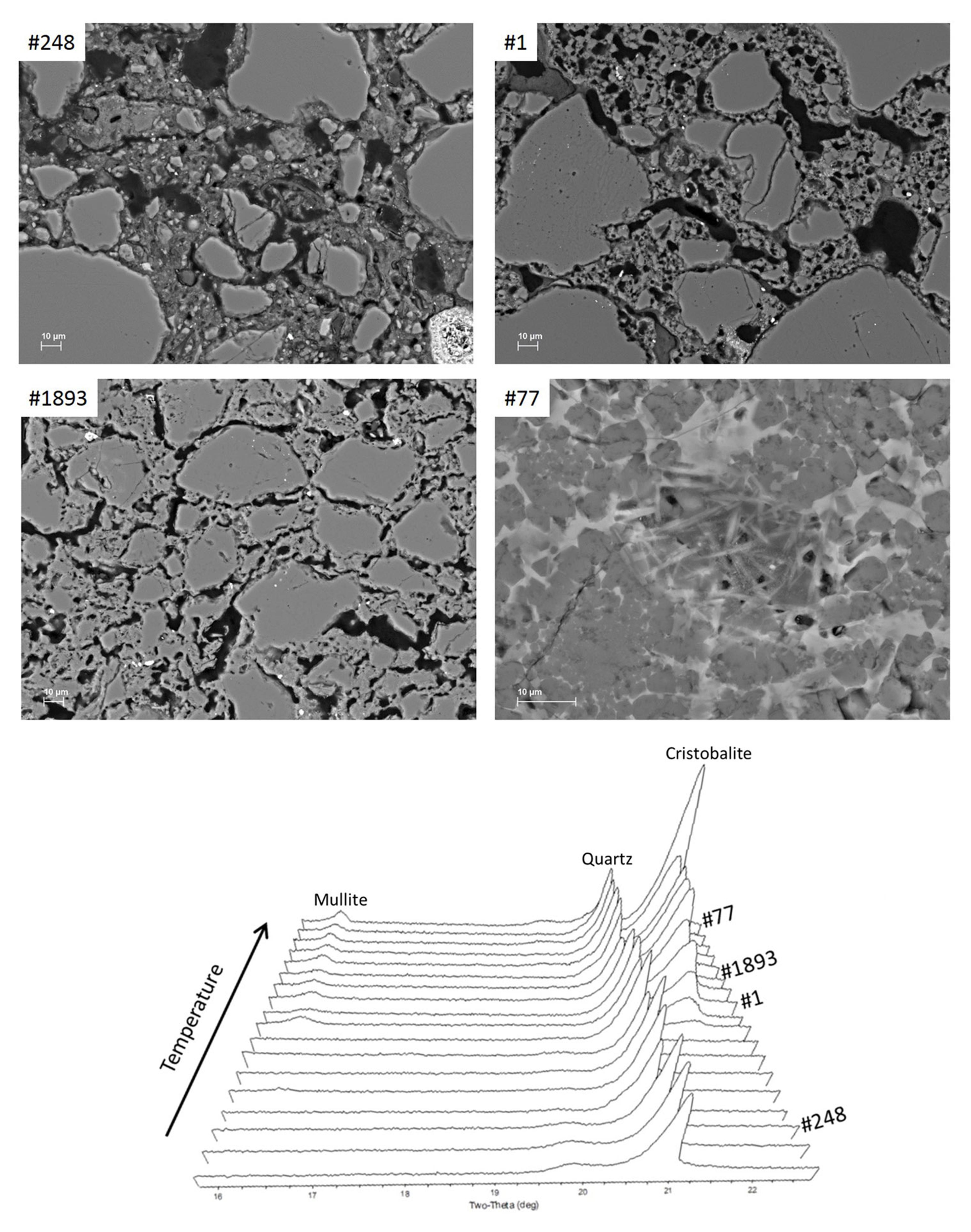

- x-ray diffraction analysis to determine the bulk mineralogy and evaluate the temperature reached by crucibles, molds and furnace walls;

- SEM-EDS analysis, to detail and refine the mineralogical composition of the non-clay fraction, evaluate bulk chemistry and localized mineralogy and chemistry, with particular attention to differences between inner, bulk and outer crucible surface.

SEM-EDS also provides semi-quantitative analysis of the metal left within or on the crucibles. Detail quantitative analysis of the metal alloys excavated from the foundry is realized by ICP-AES by the C2RMF.

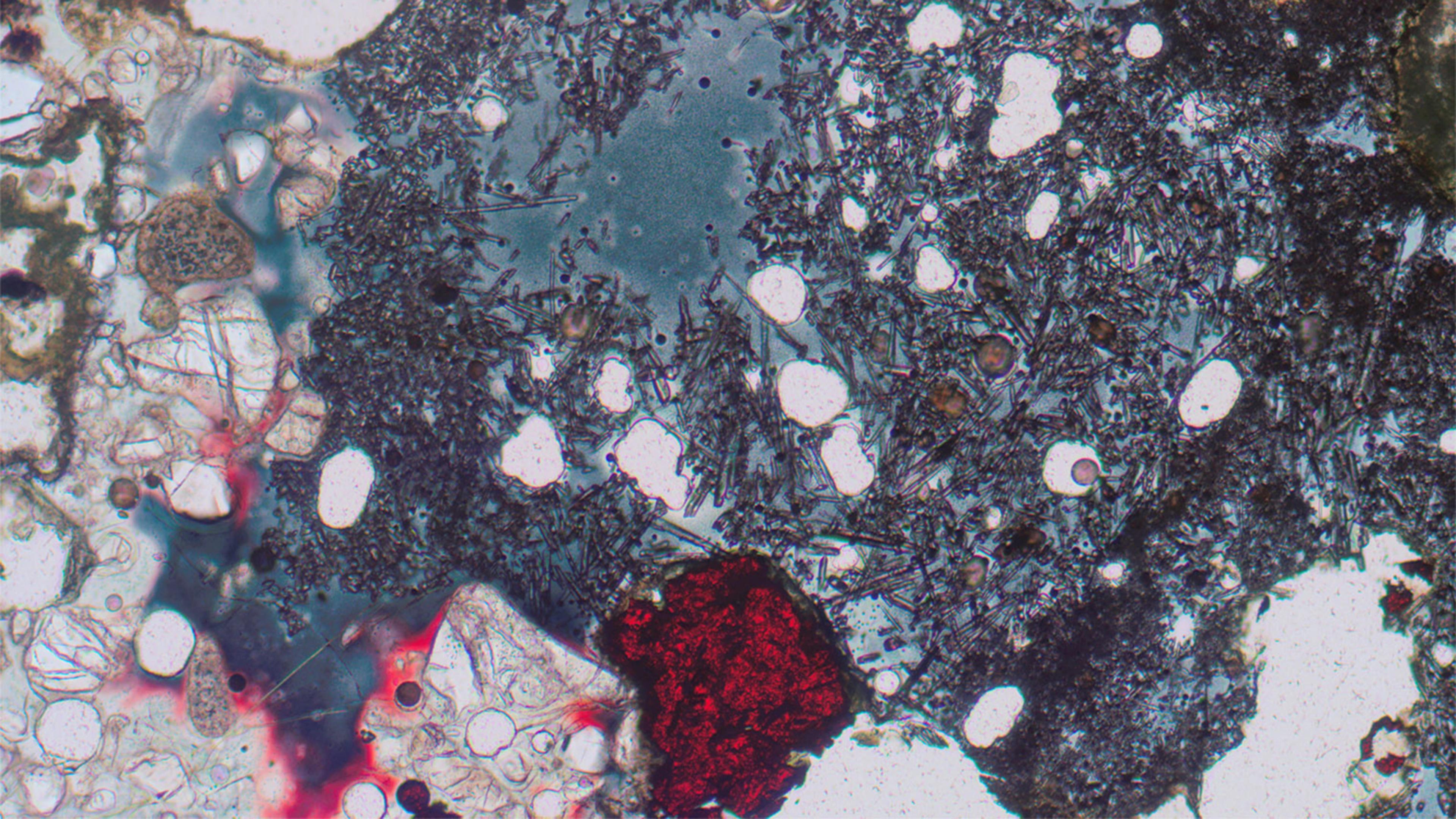

Micrographs showing examples of mineralogy and fabric of ceramic and non-ceramic samples as seen under a petrographic microscope.

Preliminary results indicate that ceramic and non-ceramic samples are characterized by very similar mineralogy and texture consisting of a very fine, poorly sorted quartz-rich framework in a kaolin-rich matrix. Among the analyzed crucibles, two main petrofabrics can be distinguish, based on the presence or absence of chaff temper (rice husk). The mineralogy of the molds, furnace floor and walls is very similar and comparable to that of crucibles. These results support the hypothesis that the same raw material, a quartz-rich, highly refractory, kaolinitic silty soil most likely imported to the site from a specific outcrop or mine, was used as floor of the workshop, and for all the clay-based objects employed in the casting process.

XRD and SEM-EDS analyses are providing useful insights into the temperatures reached by the crucibles in the furnaces. The mineralogy of the crucibles shows how mullite and cristobalite are formed at the expenses of kaolinite and quartz with increasing temperature. The presence of these two phases suggests a variable range of temperatures up to, and possibly in excess of 1,200 degrees Celsius. The high vitrification of some crucibles supports this interpretation.

The new excavation campaign will start at the beginning of 2019.

Top: Backscattered electron images showing change in texture of the crucibles' body with increasing temperature. Bottom: XRD patterns showing formation of cristobalite and mullite at high temperatures.